Robots to the Rescue to Fulfill Projected Record Volume of Holiday Gift Orders

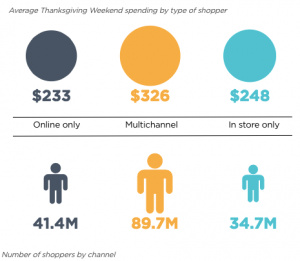

A strong economy and the rise of e-commerce have led to a record-setting year for online gift shopping. With a strapped labor market, logistics operators are relying more and more on robotics to keep distribution centers running. Optimistic holiday shoppers are starting earlier and likely spending more this year than ever. Consumers are projected to spend $717.45 billion – $720.89 billion more on holiday items than last year, a 4.3-4.8% bump in sales. More than half of that shopping will happen online. The mad rush to fulfill e-commerce orders and keep brick-and-mortar shelves stocked with inventory forces supply chain professionals to walk a fine line: one channel can’t be sacrificed for the other, especially when omnichannel shoppers are projected to outspend their single-channel counterparts by nearly $100 a head.

Source: National Retail Federation’s Annual Thanksgiving Holiday Consumer Survey, conducted by Prosper Insights & Analytics

Companies feel the talent gap strongly during the holiday season

Walking that line requires talent, which is short supply this year. Unemployment is at one of the lowest rates in history and the bar set for skills required to manage today’s complex supply chains is high, leaving a very small hiring pool as companies scramble to fill positions high and low this holiday season. This is especially true for warehouses as e-commerce continues to rise. Online fulfillment centers must pick individual orders and custom pack them to be shipped all over the world, where traditional warehouses would pack large, homogenous orders to a set number of retailers. These distribution centers need double to triple the number of workers as traditional warehouses.

Robotics to the rescue?

With the labor market tighter than ever, logistics operators are relying more and more on robotics to ensure timely fulfillment during the busy holiday season. In fact, 16.5% of companies covering a wide spread of industries now use commercial service robots. Fedex is turning to automation like robotic unloading, autonomous tugs, yard management systems and geo-fencing to handle a record-breaking peak season this year. The Gap is using robotic arms to pick and sort garment orders. Walmart is close to deploying robots to move throughout the store to check inventory and help workers find specific items. Some robots are “collaborative” in that they work along side humans like the Chuck below, while others move throughout warehouses independently, finding and picking merchandise on their own like the GreyOrange Butler.

Robotics are here to stay

Allied Market Research estimates the warehouse robot market will have a compound annual growth rate of 11.6% between 2016 and 2023, going from $2.4 billion in 2016 to $5.1 billion in 2023. Advances in the related fields of artificial intelligence, the Internet of things and the Cloud are helping to propel robotics forward. AI allows robots to navigate through complicated environments, overcome unexpected obstacles and learn from previous experiences. IoT is driving inventory management capabilities and allowing robots to receive pick lists and navigate efficiently to fulfill them. When the Cloud and IoT join forces, organizations can oversee and and operate robots remotely, from virtually anywhere with internet access. Between rising labor costs, technological advances like these and widespread early adoption across industries, the uptick in robotic fulfillment trends are here to stay. It’s likely they played a part in fulfilling your online orders this holiday season!

Ready to jump in to a career in supply chain management? Check out the UW Foster School of Business Master of Supply Chain Management Program.

Written by Victoria Pinheiro, MSc.

MSCM Content Strategy Writer

[email protected]